Are you curious about the intricate process behind the creation of CBD oil, the wellness elixir that’s taken the world by storm? In a world where natural remedies are gaining increasing popularity, understanding how CBD oil is made is a fascinating journey into the heart of this burgeoning industry. CBD, short for cannabidiol, is a non-psychoactive compound found in the cannabis plant, known for its potential health benefits. To transform cannabis plants into this sought-after oil, a meticulous extraction process is employed, harnessing the plant’s therapeutic potential without the “high” associated with its cousin, THC. This article delves into the intricate steps involved in the CBD oil production process, from selecting the right cannabis strain to extracting and refining the precious CBD-rich oil. We’ll explore the two primary methods of extraction – solvent-based and CO2-based – uncovering the pros and cons of each. You’ll also gain insights into the crucial role of quality control, ensuring that the final product meets the highest industry standards. So, whether you’re a CBD enthusiast seeking a deeper understanding of your favorite remedy or a newcomer curious about the magic behind CBD oil, this comprehensive guide will unveil the secrets of CBD oil production and empower you with knowledge about this booming wellness trend.

6 Best CBD Oil Products

We’ve spent more than 35 hours of research reviewing 25 manufacturers of CBD oil and other CBD products. We have chosen 6 of the best CBD oil companies and their products. The factors that attributed to choosing the 6 companies below include pricing, shipping speed, how quickly they respond to customer inquiries, transparency in ingredients, ease of website navigation, ease of ordering and availability of customer support.

Affiliate disclaimer: to keep our website free of any banner ads, we may receive commission from clicks on some of the links on our website. This does not compromise the quality of our editorial content in any way.

1. CBD Pure

- Extremely affordable prices

- Very fast shipping

- Organic products with a wide assortment, including CBD oil, CBD pet products for dogs and cats, CBD cream and CBD capsules

- Coupons: 10PERCENTOFF – takes 10% off your order.

2. Fab CBD

- Non-GMO ingredients and product assortment that includes CBD tinctures, CBD gummies, CBD capsules, CBD topicals and even CBD pet treats.

- Organically grown

- Flavors include mint, citrus, berry, natural flavor as well as vanilla

- From 300mg up to 2400mg

- 30 day money-back guarantee

- Free shipping ($99 and above)

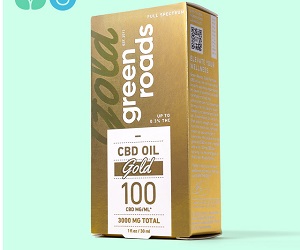

3. Green Roads CBD

The rising popularity of CBD

In recent years, CBD (cannabidiol) has experienced a surge in popularity, captivating the attention of consumers, researchers, and entrepreneurs alike. CBD is a non-intoxicating compound derived from the cannabis plant and is renowned for its potential therapeutic benefits. From alleviating anxiety and pain to improving sleep and reducing inflammation, CBD has garnered a dedicated following.

Importance of understanding CBD oil production

Behind the scenes of the CBD craze lies the crucial process of CBD oil production. How CBD is extracted, processed, and manufactured can significantly impact its quality, safety, and effectiveness. This underscores the importance of gaining a comprehensive understanding of CBD oil production methods to make informed choices as consumers and industry stakeholders.

Overview of the article

This article aims to provide a comprehensive overview of CBD oil production, from plant cultivation to the final product on the shelves. We will delve into the various methods of CBD extraction, explore the factors influencing CBD oil quality, safety, and potency, and shed light on regulatory considerations that govern this rapidly evolving industry. By the end of this article, readers will be equipped with the knowledge needed to navigate the world of CBD oil production confidently.

Understanding CBD: A Brief Introduction

What is CBD?

CBD, short for cannabidiol, is one of over 100 naturally occurring compounds found in the cannabis plant. Unlike its more famous cousin, tetrahydrocannabinol (THC), CBD is not intoxicating, meaning it does not produce a “high” when consumed. CBD is typically extracted from industrial hemp, a variety of cannabis with low THC content, although it can also be found in other strains of cannabis.

CBD interacts with the body’s endocannabinoid system (ECS), a complex network of receptors and neurotransmitters involved in regulating various physiological functions, including mood, pain perception, immune response, and sleep. By interacting with the ECS, CBD can influence these functions and potentially provide therapeutic benefits.

Health benefits and potential uses

The therapeutic potential of CBD has sparked considerable interest among researchers, healthcare professionals, and consumers. While more research is needed to fully understand its effects, several potential health benefits and uses of CBD have been explored:

- Pain Management: CBD may help alleviate chronic pain by interacting with receptors in the ECS and reducing inflammation.

- Anxiety and Depression: Some studies suggest that CBD may have anxiolytic (anxiety-reducing) and antidepressant effects by modulating serotonin receptors in the brain.

- Sleep: CBD has been investigated for its potential to improve sleep quality and manage sleep disorders like insomnia.

- Neurological Conditions: Epidiolex, a CBD-based medication, has been approved by the FDA for the treatment of certain forms of epilepsy.

- Anti-inflammatory: CBD’s anti-inflammatory properties may be beneficial in managing conditions characterized by inflammation, such as arthritis.

- Skin Health: Topical CBD products are used to address skin conditions like acne and eczema due to their potential anti-inflammatory and antimicrobial properties.

- Stress Reduction: Some individuals use CBD to manage stress and promote a sense of calm.

Legal status of CBD

The legal status of CBD varies from country to country and even within different regions of the same country. In the United States, for example, the legal framework for CBD is complex:

- Federal Level: In 2018, the U.S. Farm Bill legalized the cultivation and sale of industrial hemp and its derivatives, including CBD, as long as the THC content does not exceed 0.3%. CBD derived from hemp is legal at the federal level.

- State Regulations: States have varying regulations regarding the production, sale, and use of CBD. Some states have embraced CBD, allowing it to be sold in various forms, while others have more restrictive laws.

- FDA Oversight: The U.S. Food and Drug Administration (FDA) retains authority over the marketing and labeling of CBD products, particularly those making health claims. This means that CBD products intended for therapeutic use must go through an FDA approval process.

It’s essential for consumers and producers to stay informed about the legal status of CBD in their specific location, as regulations can change over time. Additionally, the legal status of CBD varies internationally, with some countries allowing unrestricted access to CBD products, while others have stricter regulations.

Sourcing High-Quality Hemp

The importance of starting with quality hemp

The quality of hemp used as a source for CBD oil production is paramount. The saying “garbage in, garbage out” holds true in this context. Starting with high-quality hemp plants not only ensures a better end product but also influences the safety and effectiveness of CBD oil. Here’s why it’s crucial:

- Cannabinoid Profile: Quality hemp should have a well-balanced cannabinoid profile with high CBD content and minimal THC (below 0.3% to comply with legal standards). A precise cannabinoid profile is essential for consistent and predictable CBD oil.

- Terpenes: Terpenes are aromatic compounds found in hemp that contribute to the flavor and potential therapeutic effects of CBD oil. High-quality hemp retains a rich terpene profile, enhancing the overall product’s quality and efficacy.

- Safety: Hemp plants can absorb toxins and heavy metals from the soil, posing health risks if not properly tested and regulated. Quality hemp is grown in clean, safe environments and is rigorously tested for contaminants.

- Efficacy: The therapeutic potential of CBD is closely tied to the quality of the hemp. High-quality hemp can produce CBD oil that is more effective in addressing various health concerns.

Hemp cultivation and selection criteria

- Strain Selection: The choice of hemp strain plays a vital role in CBD production. Breeders have developed specific strains for high CBD content and low THC levels. These strains are preferred for CBD oil production to ensure compliance with legal regulations and maximize CBD yield.

- Growing Conditions: Hemp is a resilient plant, but its quality can be influenced by environmental factors. Ideal growing conditions include the right climate, soil quality, and adequate water supply. Regions with consistent sunlight and well-draining soil are often chosen for hemp cultivation.

- Cultivation Practices: Hemp can be grown indoors, in greenhouses, or in open fields. Each method has its advantages and challenges. Indoor cultivation allows for precise control of environmental factors, while outdoor cultivation can produce larger yields but may be more susceptible to pests and environmental fluctuations.

- Testing and Certification: Reputable hemp growers conduct regular testing throughout the growing season to monitor cannabinoid levels, terpene profiles, and the absence of contaminants. Certifications such as Good Agricultural Practices (GAP) and Good Manufacturing Practices (GMP) demonstrate commitment to quality.

Organic vs. conventional farming

The choice between organic and conventional farming methods can significantly impact the quality of hemp:

- Organic Farming: Organic hemp is grown without synthetic pesticides, herbicides, or chemical fertilizers. It relies on natural pest control and soil enrichment techniques. Organic practices promote soil health and reduce the risk of chemical residues in the final product. Many consumers prefer CBD products derived from organically grown hemp due to concerns about chemical exposure.

- Conventional Farming: Conventional farming may use synthetic chemicals to boost crop yields and protect against pests. While this approach can produce high yields, it may also result in a higher likelihood of chemical residues in the plant material. Strict regulations exist to limit the use of certain chemicals in hemp cultivation, but consumers should be aware of the farming practices of the hemp source.

In conclusion, sourcing high-quality hemp is the foundational step in CBD oil production. A well-chosen hemp strain, proper cultivation practices, and adherence to organic principles can all contribute to the production of safe, effective, and reliable CBD oil. Buyers and producers should prioritize transparency, quality testing, and adherence to regulations when selecting their hemp source.

Harvesting and Drying

Optimal harvest time for hemp

The timing of the hemp harvest is a critical factor in determining the quality and cannabinoid content of the final CBD oil product. Harvesting too early or too late can impact CBD levels and the overall quality of the crop. Here’s a detailed look at the optimal harvest time for hemp:

- Flowering Stage: Hemp plants typically enter the flowering stage when they reach maturity. This stage is characterized by the development of flowers and the accumulation of cannabinoids, including CBD. The ideal harvest time for CBD-rich hemp is often during the late flowering stage.

- Cannabinoid Maturation: CBD content tends to increase as the plant matures. Harvesting too early can result in lower CBD levels, while harvesting too late can lead to an increase in THC levels, potentially exceeding legal limits. Timing the harvest when CBD content is at its peak is essential for quality.

- Testing: To determine the optimal harvest time, hemp growers should conduct regular testing of their crops. This involves measuring cannabinoid levels, particularly CBD and THC. Testing ensures compliance with legal regulations and allows for precise timing of the harvest.

- Terpene Profile: The terpene profile, which contributes to the aroma and flavor of the final product, can also vary with the timing of the harvest. Some strains may have a more desirable terpene profile when harvested slightly earlier or later.

Drying techniques and their impact on CBD content

Proper drying is a crucial step after harvesting hemp. Drying the hemp plants effectively preserves the cannabinoid content and minimizes the risk of mold and degradation. Here are some detailed considerations regarding drying techniques and their impact on CBD content:

- Indoor vs. Outdoor Drying: Hemp can be dried indoors in controlled environments or outdoors in the open air. Indoor drying allows for precise control of temperature and humidity, which can help preserve CBD content. Outdoor drying may be faster but can be less controlled.

- Temperature and Humidity Control: Ideally, hemp should be dried at a controlled temperature (around 60-70°F or 15-21°C) with humidity levels maintained between 45% and 55%. Rapid drying at higher temperatures can degrade cannabinoids, including CBD, and result in a lower-quality product.

- Air Circulation: Proper air circulation is essential to prevent mold growth and ensure even drying. Hanging hemp plants or using drying racks with adequate spacing can facilitate airflow.

- Curing: After the initial drying process, some hemp producers choose to cure the plants. Curing involves storing the dried hemp in a controlled environment for a specified period, often several weeks. This process can enhance the flavor and aroma of the final product and may also affect the cannabinoid profile.

- Testing During Drying: To monitor the drying process and preserve CBD content, regular testing is essential. Testing can indicate when the hemp is sufficiently dried and ready for further processing.

Importance of preventing mold and contamination

Preventing mold and contamination during the drying process is of utmost importance to ensure the safety and quality of the final CBD oil product:

- Mold Growth: Hemp is susceptible to mold growth if not dried properly. Mold can produce harmful mycotoxins that pose health risks when consumed. Proper drying conditions and monitoring for mold are critical.

- Contaminants: Contaminants can be introduced during drying if equipment and drying areas are not adequately sanitized. Contaminants, including bacteria and foreign particles, can compromise the quality and safety of CBD oil.

- Quality Control: Implementing strict quality control measures during the drying process is essential. This includes regular inspection, testing for mold and contaminants, and adherence to hygiene and sanitation standards.

In conclusion, harvesting hemp at the optimal time, employing effective drying techniques, and preventing mold and contamination are crucial steps in producing high-quality CBD oil. These processes directly impact the cannabinoid content, safety, and overall quality of the final product, making them essential considerations for hemp growers and CBD manufacturers.

Extracting CBD from Hemp

Various extraction methods

The extraction of CBD from hemp involves separating the desired compounds, including CBD, from the plant material. There are several methods used for this purpose, each with its own advantages and disadvantages. Here, we’ll explore three primary extraction methods:

- CO2 Extraction (Supercritical CO2 Extraction):CO2 extraction is a popular method in the CBD industry due to its efficiency and safety. It involves using carbon dioxide in various states (liquid, solid, and gas) to extract CBD from hemp.

- Solvent-Based Extraction:Solvent-based extraction uses organic solvents, such as ethanol or hydrocarbons like butane or propane, to dissolve CBD and other cannabinoids from the plant material.

- Ethanol Extraction:Ethanol extraction specifically utilizes ethanol as a solvent to separate CBD and other compounds from hemp.

Pros and cons of each extraction method

- CO2 Extraction:Pros:

- High selectivity, allowing for precise targeting of specific compounds.

- Produces a high-quality CBD extract with minimal impurities.

- Generally considered safe, as CO2 is non-toxic and non-flammable.

- Can be adjusted for temperature and pressure control, allowing for customization.

Cons:

- Equipment for CO2 extraction can be expensive.

- Requires skilled operators to ensure optimal results.

- Some setups may have limited throughput for large-scale production.

- Solvent-Based Extraction:Pros:

- Generally cost-effective, making it accessible to small-scale producers.

- Can efficiently extract a wide range of compounds from hemp.

- Suitable for both small and large-scale production.

Cons:

- Requires careful removal of residual solvents to ensure safety.

- May extract undesirable compounds along with cannabinoids.

- Safety concerns due to flammable solvents if not handled properly.

- Ethanol Extraction:Pros:

- Generally regarded as safe for consumption when properly purged.

- Efficient extraction of cannabinoids and terpenes.

- More cost-effective than CO2 extraction equipment.

Cons:

- Extraction may not be as selective as CO2, potentially leading to impurities.

- Requires additional steps to remove residual ethanol.

- Ethanol can also extract chlorophyll, affecting the flavor of the final product.

The role of temperature and pressure in extraction

Temperature and pressure play critical roles in the efficiency and selectivity of CBD extraction methods, particularly in CO2 extraction:

- CO2 Extraction:

- Temperature: CO2 can exist as a gas, liquid, or supercritical fluid depending on temperature and pressure. By adjusting temperature, operators can control the solubility of specific compounds, allowing for targeted extraction.

- Pressure: Higher pressures are used to maintain CO2 in its supercritical state, enhancing its solvent properties. This allows for better extraction of cannabinoids like CBD.

- Solvent-Based Extraction:

- Temperature: Temperature control in solvent-based extraction methods is critical to prevent the loss of desirable compounds or the introduction of impurities. For example, ethanol extraction is typically performed at low temperatures to minimize unwanted reactions.

- Pressure: Pressure control in solvent-based methods is less significant compared to CO2 extraction. It primarily depends on the type of solvent used and the desired outcome.

In summary, the choice of CBD extraction method depends on factors such as scale of production, safety considerations, and desired product quality. Each method has its own set of pros and cons, and temperature and pressure control are crucial for optimizing extraction efficiency and product quality, especially in CO2 extraction.

Refining the Extract

Winterization and filtration

After the initial CBD extraction, the crude extract may contain impurities, waxes, lipids, and other unwanted compounds. Winterization and filtration are essential steps in the refining process to improve the purity and quality of the CBD extract.

- Winterization:

- Winterization is a process that involves dissolving the crude CBD extract in a solvent, typically ethanol or a similar alcohol.

- The mixture is then cooled to very low temperatures, usually around -20°C (-4°F) or lower. This causes the fats, waxes, and lipids present in the extract to solidify and precipitate out of the solution.

- After the precipitates form, the solution is filtered, removing the undesired components. The resulting liquid is now winterized CBD extract, which is purer and less viscous.

- Filtration:

- Filtration is a crucial step in removing any remaining solid impurities or particulates from the winterized CBD extract.

- Several filtration methods can be employed, including gravity filtration, vacuum filtration, or even specialized filtration equipment like rotary vacuum filters.

- Filtration helps clarify the extract and ensures that it is free of any visible particles.

Decarboxylation of CBD-A to CBD

CBD in its natural form within the hemp plant is typically found as CBD-A (cannabidiolic acid), which is non-psychoactive and requires decarboxylation to become the active compound CBD (cannabidiol). Decarboxylation is an essential step in the CBD refinement process.

- Decarboxylation Process:

- Decarboxylation involves heating the CBD-A extract to a specific temperature, typically between 220°C (428°F) and 240°C (464°F), for a specified time.

- This process removes the carboxyl group (COOH) from CBD-A, converting it into CBD. The decarboxylated CBD is then more bioavailable and active for therapeutic use.

- Importance of Decarboxylation:

- Decarboxylation ensures that the CBD extract has the desired pharmacological effects.

- It also improves the taste and aroma of the final product, as decarboxylated CBD has a milder and more pleasant flavor compared to CBD-A.

Removing impurities and unwanted compounds

Refining the CBD extract involves further purification to remove any remaining impurities and unwanted compounds. Several techniques can be used for this purpose:

- Chromatography:

- Chromatography methods, such as flash chromatography or preparative high-performance liquid chromatography (HPLC), can be employed to separate and isolate CBD from other cannabinoids or impurities.

- These methods allow for precise control over compound separation and can result in highly pure CBD.

- Distillation:

- Distillation methods, such as short path distillation or fractional distillation, can be used to further refine the CBD extract.

- These techniques can separate CBD from other compounds based on differences in boiling points, resulting in a highly concentrated and purified CBD distillate.

- Crystallization:

- Crystallization involves cooling the CBD extract to promote the formation of CBD crystals, which can be separated and purified.

- This method is often used to produce pure CBD isolate, which is almost 100% pure CBD.

- Solvent Removal:

- Any residual solvents from the extraction process, such as ethanol or CO2, must be completely removed to ensure the final product is safe for consumption.

- This is typically achieved through processes like rotary evaporation or vacuum purging.

In conclusion, refining the CBD extract is a crucial step in producing high-quality CBD products. Winterization and filtration remove impurities, decarboxylation activates CBD, and additional purification methods like chromatography, distillation, crystallization, and solvent removal further enhance the purity and potency of the final CBD product. These processes are essential to meet industry standards and ensure consumer safety and satisfaction.

Formulating CBD Products

Different types of CBD products

CBD is a versatile compound that can be incorporated into various product types to cater to different consumer preferences and needs. Here, we’ll explore some of the most common types of CBD products:

- Tinctures:

- CBD tinctures are liquid extracts of CBD that can be taken sublingually (under the tongue) for rapid absorption.

- They are typically made by diluting CBD extract with a carrier oil (such as MCT oil) and often come in dropper bottles for precise dosing.

- Capsules:

- CBD capsules are a convenient way to consume a precise dose of CBD.

- The CBD extract is typically mixed with a carrier oil and then encapsulated in gelatin or vegan-friendly capsules.

- Topicals:

- CBD topicals include creams, balms, salves, and lotions infused with CBD.

- They are applied directly to the skin and are designed for targeted relief of pain, inflammation, or skin issues.

- Edibles:

- CBD edibles are food products infused with CBD, such as gummies, chocolates, or beverages.

- They offer a tasty and discreet way to consume CBD and can take longer to produce effects as they need to be digested.

Adding carrier oils and flavorings

- Carrier Oils:

- Many CBD products, including tinctures and capsules, require the addition of carrier oils to dilute the concentrated CBD extract and improve its bioavailability.

- Common carrier oils include MCT (medium-chain triglyceride) oil, hemp seed oil, coconut oil, and olive oil.

- The choice of carrier oil can impact the flavor, shelf life, and absorption rate of the CBD product.

- Flavorings:

- To enhance the taste of CBD products, manufacturers often add natural or artificial flavorings.

- For tinctures and edibles, flavorings like fruit extracts, mint, or vanilla can make the product more palatable.

- Flavorings should be carefully chosen to complement the overall product and avoid overwhelming the natural taste of CBD.

Meeting regulatory requirements for labeling and packaging

- Labeling Requirements:

- CBD product labeling must comply with local and national regulations, which can vary widely.

- Common labeling requirements include stating the CBD content in milligrams per serving, the total volume or quantity of the product, the manufacturer’s information, and directions for use.

- Additionally, labels should include any necessary warnings, such as “Keep out of reach of children” or “Not intended for pregnant or nursing individuals.”

- Third-Party Testing:

- To ensure product safety and transparency, many reputable CBD manufacturers conduct third-party testing of their products.

- These tests assess the CBD content, confirm the absence of contaminants like heavy metals and pesticides, and verify that THC levels are within legal limits.

- Packaging:

- CBD products should be packaged in containers that protect them from light, air, and moisture to maintain their potency.

- Child-resistant packaging may be required in some regions to prevent accidental ingestion.

- Compliance with Regulations:

- Manufacturers must stay informed about evolving CBD regulations in their target markets and ensure their products meet all legal requirements.

- Compliance with regulations not only helps ensure product safety but also builds consumer trust.

In summary, formulating CBD products involves choosing the product type that best suits the intended use, incorporating carrier oils and flavorings for improved taste and bioavailability, and adhering to strict regulatory requirements for labeling and packaging. Meeting these requirements is essential to produce safe, effective, and legally compliant CBD products for consumers.

Conclusion

Recap of the CBD production process

The journey from hemp cultivation to the final CBD product is a complex and highly regulated process. To recap the key stages of CBD production:

- Sourcing High-Quality Hemp: It all begins with selecting and cultivating high-quality hemp plants with the right cannabinoid profile and minimal contaminants.

- Harvesting and Drying: Hemp must be harvested at the optimal time, dried carefully, and monitored for mold and contaminants to ensure the integrity of the plant material.

- Extracting CBD from Hemp: CBD can be extracted using various methods, including CO2 extraction, solvent-based extraction, and ethanol extraction, with each method having its pros and cons.

- Refining the Extract: Winterization and filtration remove impurities, decarboxylation converts CBD-A to active CBD, and additional purification methods further enhance the purity and potency of the CBD extract.

- Formulating CBD Products: CBD can be incorporated into various products, such as tinctures, capsules, topicals, and edibles, by mixing it with carrier oils, flavorings, and other ingredients to meet consumer preferences.

The importance of transparency in CBD production

Transparency is a cornerstone of responsible CBD production. It involves openly sharing information about the entire production process, from seed to shelf. Here’s why transparency is crucial:

- Consumer Trust: Transparent practices build trust with consumers, who deserve to know what they are putting into their bodies.

- Quality Assurance: Transparency ensures that each step of the production process is carefully monitored and controlled to produce safe and high-quality CBD products.

- Regulatory Compliance: Transparency helps CBD producers comply with ever-evolving regulations, reducing the risk of legal issues and ensuring consumer safety.

- Product Differentiation: In a crowded market, transparent companies can stand out by demonstrating their commitment to quality and ethics.

Future trends and innovations in CBD oil production

The CBD industry is dynamic and continually evolving. Here are some future trends and innovations to watch for in CBD oil production:

- Advanced Extraction Techniques: Ongoing research is likely to lead to more efficient and sustainable extraction methods, reducing production costs and environmental impact.

- Customized Formulations: CBD producers may offer more personalized products, allowing consumers to tailor CBD concentrations, terpene profiles, and other factors to their specific needs.

- Regulatory Clarity: As regulations evolve, clearer guidelines for CBD production and labeling are expected, providing greater consistency and safety for consumers.

- Alternative Cannabinoids: Research into minor cannabinoids like CBG (cannabigerol) and CBN (cannabinol) may lead to the development of new products targeting specific health conditions.

- Sustainable Practices: Hemp cultivation and CBD production are likely to become more sustainable, with a focus on eco-friendly farming methods and packaging.

- Nanoencapsulation: This technology may improve the bioavailability of CBD, making products more effective at lower doses.

- Global Expansion: As CBD regulations become more standardized worldwide, international markets are expected to grow, leading to increased innovation and competition.

In conclusion, CBD oil production is a multifaceted process that demands precision, transparency, and commitment to quality. As the industry matures, consumers can look forward to safer and more innovative CBD products that cater to their specific needs, while producers will continue to adapt to meet evolving regulations and market demands.